Powder coating is not just a surface treatment—it is a precision-driven industrial process designed to protect metal, extend lifespan, and enhance performance in extreme environments like the UAE.

From construction and automotive parts to marine and industrial equipment, powder coating delivers durability that traditional paints cannot match.

In this complete guide, we break down the step-by-step powder coating process, starting from sandblasting preparation to final curing and inspection—so decision-makers understand exactly why quality coating begins long before color is applied.

Every successful powder coating job begins with inspection. Metal surfaces are evaluated for:

This assessment determines the correct sandblasting media, pressure, and coating system required for optimal results.

Sandblasting (abrasive blasting) is the most critical stage in the powder coating process. It removes contaminants and creates a uniform surface profile that allows powder to bond permanently.

Different materials require different blasting media, such as garnet, steel grit, or aluminum oxide—selected based on application and industry standards.

After sandblasting, surfaces are thoroughly cleaned to remove:

This step ensures the metal is chemically clean, preventing pinholes, bubbling, or weak adhesion during coating.

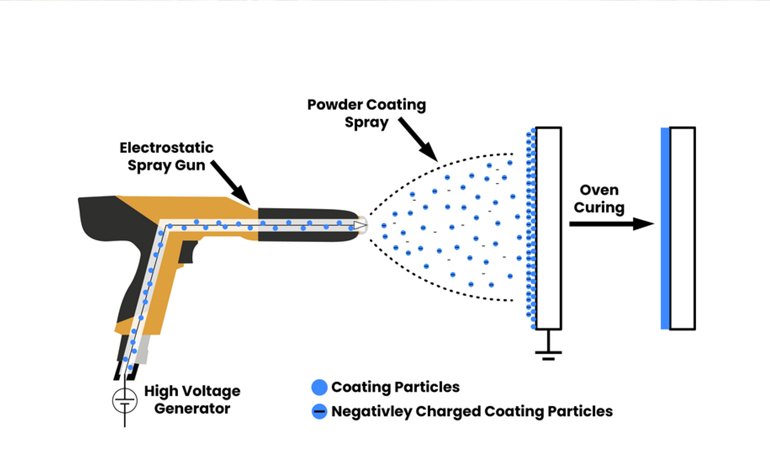

Once prepared, the metal enters the powder application stage. Using electrostatic spray guns, powder particles are charged and evenly attracted to the grounded metal surface.

This step defines the aesthetic quality of the final product, but relies entirely on earlier preparation for durability.

After application, coated components are transferred into curing ovens where heat melts and chemically bonds the powder to the metal.

Typical curing conditions:

Curing transforms powder into a hard, seamless protective layer resistant to corrosion, UV exposure, and mechanical wear.

Once cured, parts are cooled naturally and inspected for:

Professional coating providers follow strict inspection protocols to ensure every component meets industrial performance standards.

These transformations highlight why powder coating is trusted across construction, automotive, marine, and industrial sectors.

Industries choose powder coating not for appearance—but for performance under pressure.

Its adaptability makes it the go-to coating solution for demanding environments.

The full process—from sandblasting to curing—typically takes 1–3 days depending on component size, surface condition, and coating requirements. Proper preparation is prioritised over speed to ensure durability and performance.

Yes. Sandblasting ensures proper surface preparation by removing rust, contaminants, and old coatings. Skipping this step significantly reduces adhesion and can lead to premature coating failure, especially in UAE environmental conditions.

With correct preparation and application, powder coating can last 10–20 years or more. It offers superior resistance to corrosion, UV exposure, and wear compared to traditional liquid paints.

Yes. Powder coating produces minimal waste, contains no solvents, and releases virtually no VOCs, making it an environmentally responsible coating option for industrial and commercial applications.

If you’re planning a project that demands durability, corrosion resistance, and long-term value, powder coating is the proven solution. Contact us today to get expert powder coating services tailored to your industry needs.